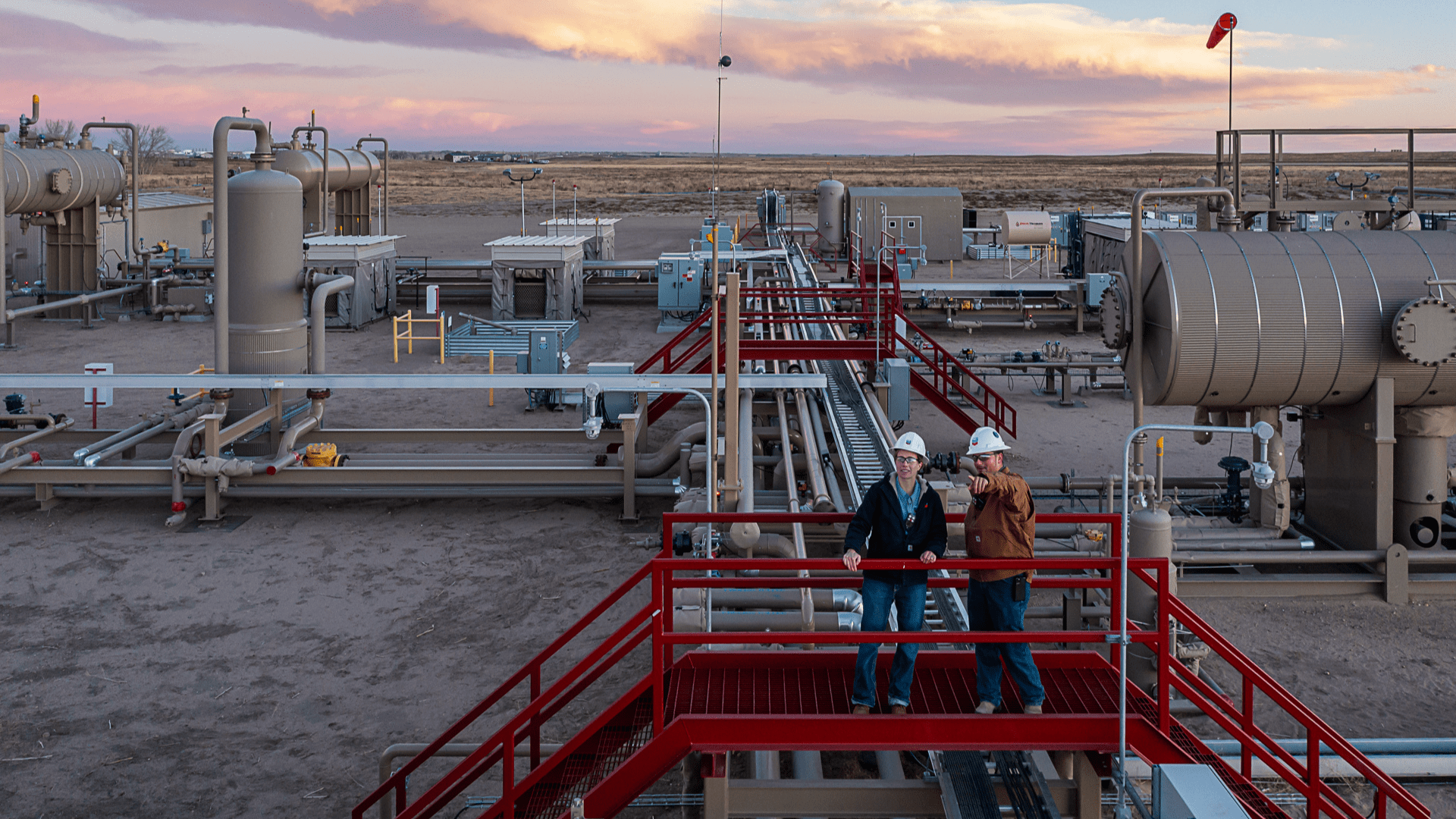

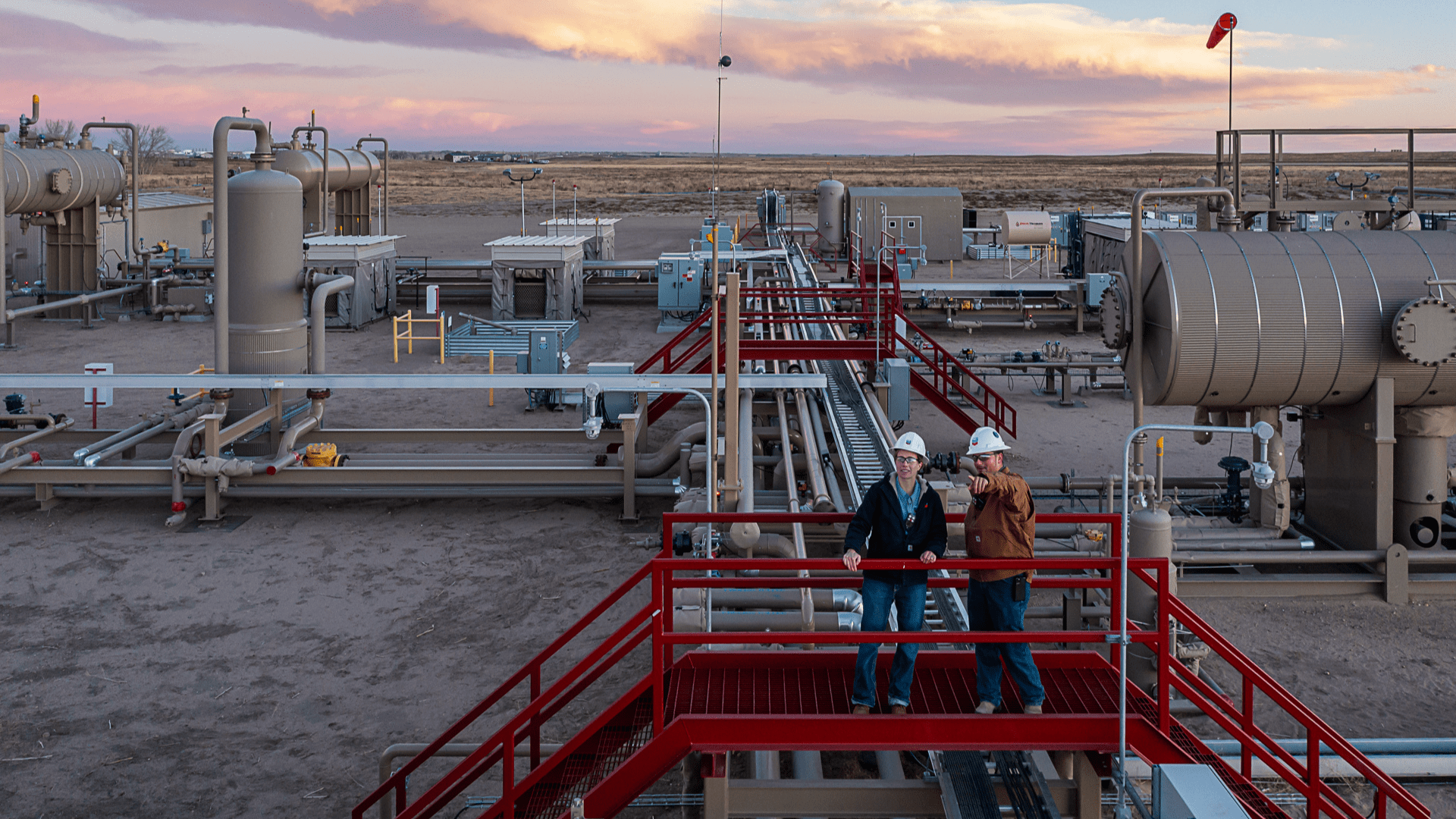

The demand for clean energy is high in the United States, and companies are finding ways to address it while providing crucial resources. In Colorado, one company uses innovation and technology to provide lower-carbon energy. Chevron utilizes tankless facilities to address low-carbon demands.

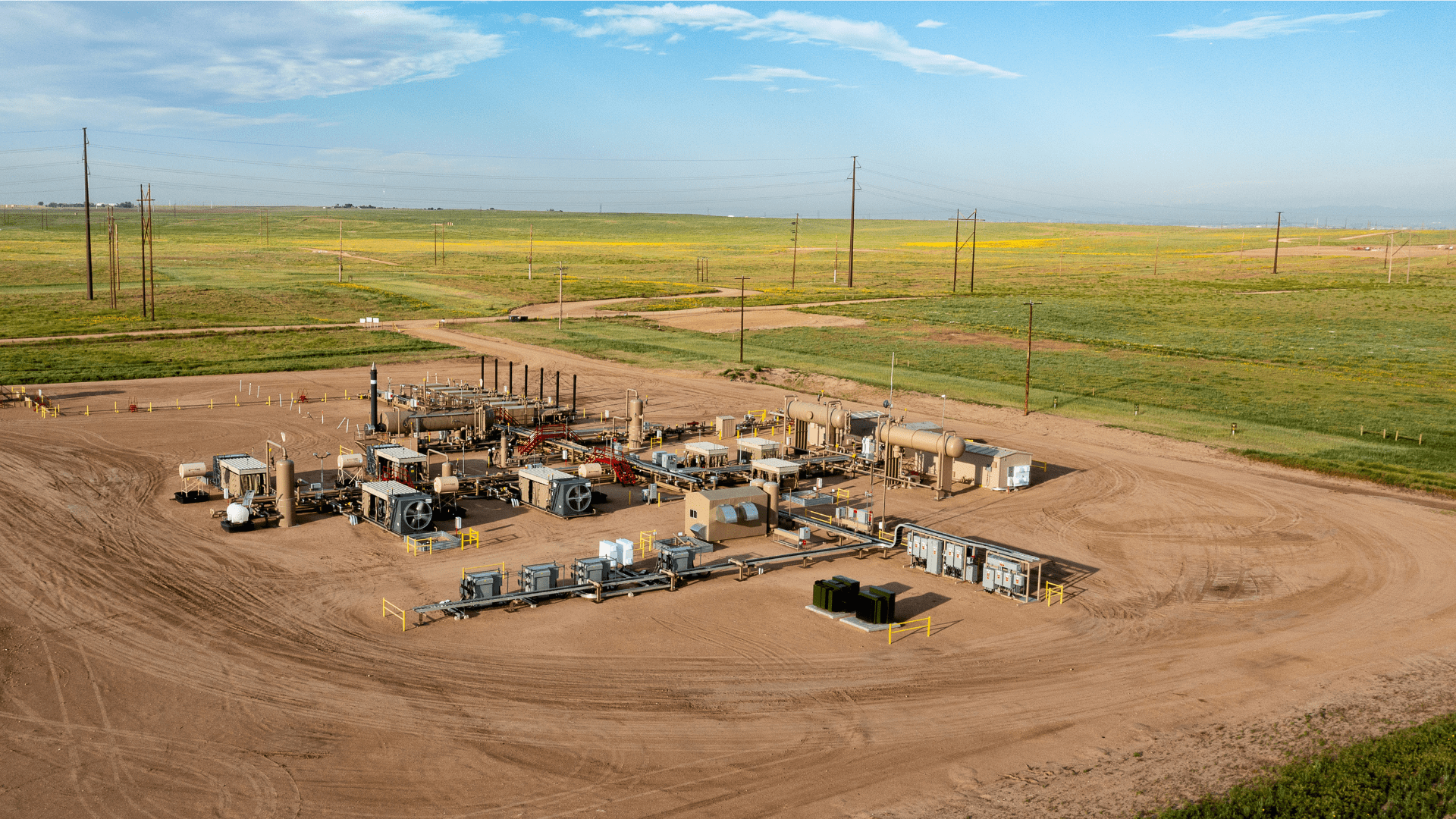

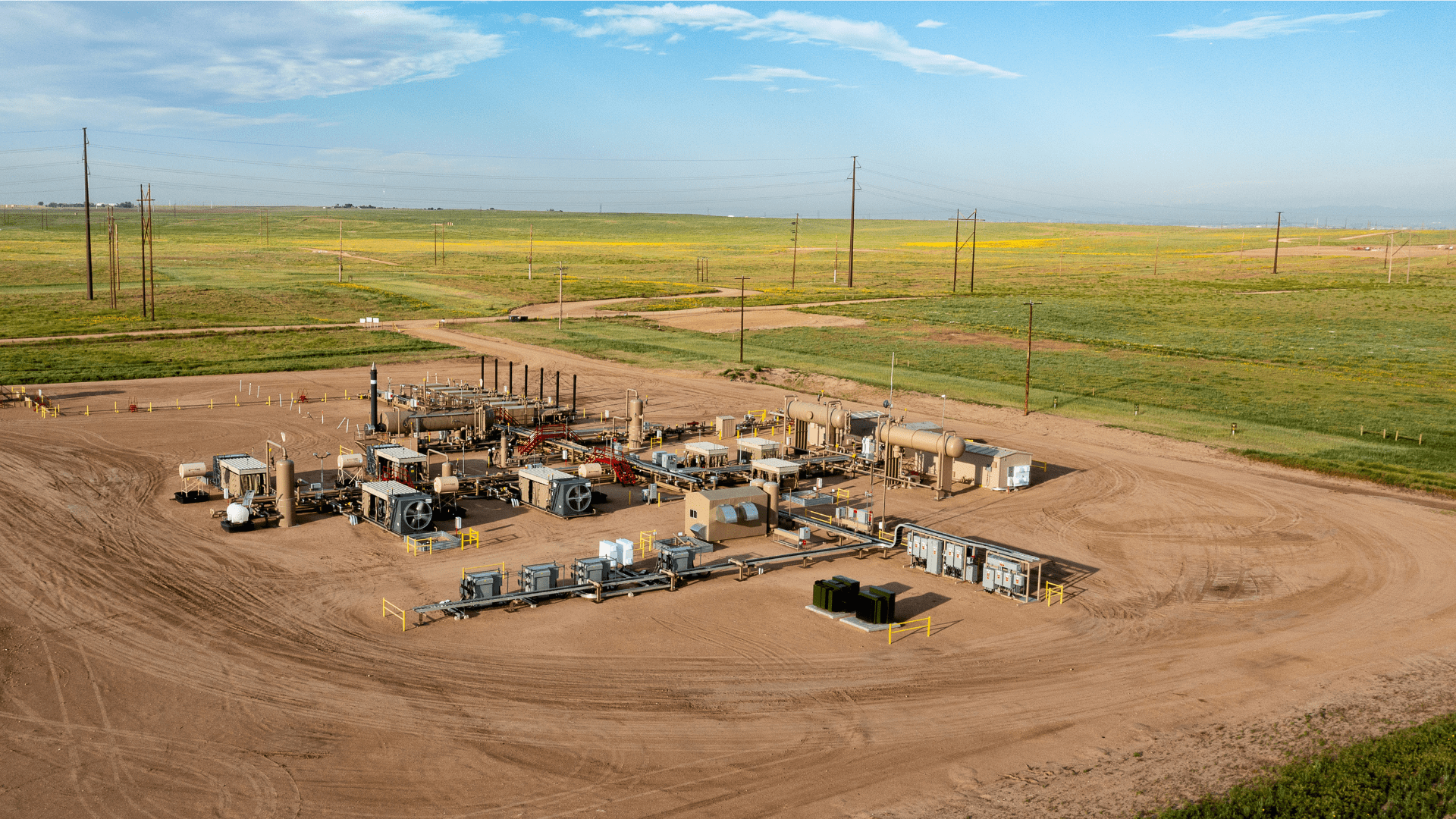

Tankless Facilities

Traditionally, after drilling oil and gas wells, the product would be delivered to production facilities with tanks on them. This process involves trucks pulling the oil from those tanks to deliver them to markets in the state and nationwide. That’s no longer the case for Chevron because of tankless facilities.

These facilities use different technology and infrastructure, like pipelines, to deliver the product safely. One benefit of tankless facilities is eliminating the traffic of the production trucks, thus lowering carbon emissions. Chevron’s website states, “Our newest facilities enable us to eliminate more than 90 percent of greenhouse gas emissions compared to older facility designs.”

Chevron has been on the tankless journey for several years. Before, the company drilled wells and built many smaller tank batteries in an area to handle and process the fluids. “Today, we aggregate production from up to 20 square miles around us to this one single location,” said Luke McCartney with Chevron. “We’re tankless by design here, which means no truck traffic.”

Chevron’s Mustang comprehensive drilling plan (CDP) is a “blueprint for lower-carbon energy development.” The company website says it supports its goal of minimizing its surface footprint in and around communities. In the Mustang CDP area, it only takes about 7.5 surface acres to deliver the same production volume that previously required 400 surface acres. Tankless production reduced the company’s surface footprint by 95 percent.

“It’s a massive change for the industry,” said McCartney.

Tune in to the Science Channel to watch Clean Slate at 10 AM on Saturday, September 21!