unspun is a sustainable fashion company built around zero inventory and made-to-order, perfectly fitted jeans. Thanks to their innovative technology, their ultimate goal is to reduce global human carbon emissions by 1 percent. We talked to unspun’s Co-Founder Kevin Martin about how unspun creates a perfect pair of jeans, the apparel industry’s biggest problem, and why Gen Z makes him optimistic about the future of sustainable fashion.

Tomorrow’s World Today (TWT): What was the initial inspiration behind starting unspun?

unspun’s Kevin Martin (KM): Beth, one of our three founders, was the original visionary. I think maybe a better phrase than inspired is appalled. She would sit in meetings where the discussion was along the lines of “Opt Outside,” “Save the Environment,” and “Leave No Trace,” but in the same meeting they would talk about how donating extra clothes to the homeless makes the brand look bad so they need to burn them. Her thought was “are you kidding me?”

She understood that the fashion industry is still ruled by sales, profits, and capitalism, but she also cared about sustainability. She knew there had to be a technological solution that gets rid of the need for inventory and makes what we actually need.

TWT: What makes the jeans so sustainable?

KM: unspun is a Certified B Corporation, which is a really hard sustainability rating to achieve. We achieved this by everything being sustainable: the actual ingredients, the actual cotton, how we wash or laser our products instead of the energy or water-intensive processes, and the inventory.

We source from extremely sustainable partners who have a similar mindset to us. We ask ourselves questions like: Can we find some sort of bio-based product rather than a chemical-based one? Are we working with mills that are fully LEED certified? Can we use yarns that work really well with lasers?

TWT: From sustainability to accessibility, there are many things that make unspun’s jeans unique. What excites you the most?

KM: I think the coolest part is that unspun betters the environment while providing a better experience for the customer. We often have people emailing us that they haven’t been able to wear jeans in years because their thighs are big, their waist is small, their waist and hips don’t match the length of their legs, etc. So many people feel like they’re in this excluded minority of not finding things that fit, so when we get to make them something that actually fits them, those moments are so cool because it’s like they’ve almost given up before they found us.

TWT: How do your jeans fit so well?

TWT: Can you talk a bit more about the technology behind the perfect fit? How do you take the 10-second body scan from your app and turn it into a pair of jeans?

KM: unspun uses the Face ID sensor on iPhones, which inherently is depth data…Face ID gives the distance of how far away the pixels are.

For the [10-second body scan], you wear tight-fitting clothes, and you stand away from your phone so that you’re fully in view. You spin around 360 degrees over 10 seconds in a sort of A shape, and we keep taking these depth images. The output of an unspun scan is a literal millimeter accurate, full Digital Twin 3D model of your legs that stitches together all of those images and data points taken as your body rotated.

We then take that 3D model of your legs, pair it with the style and fabric you ordered, and put them into this fit engine that we’ve developed. The fit engine looks at the shape of your body, its volume, the way that your curves interact with each other, and the style that you ordered, and we digitally design your pair of jeans. We run some modeling and analysis on it, basically making a ton of pants for you and comparing them to other similar models, to optimize them for each unique person.

By the time we send something to the factory, we’ve done hundreds of iterations on what the perfect pair of pants should be for you so we can be really confident that this is something that will fit well on your unique body shape. Those pants will be completely different from every other pair we’ve ever made. Even if you bought the same pair of pants in a different fabric, the pants would change because the different fabric has different profiles. The jeans are hyper-optimized to you, the shape of your legs, and the actual product that you’re going to wear.

TWT: How are unspun’s jeans currently made? As unspun continues to grow in popularity, will the production of the jeans change?

KM: The first phase of the brand today is everything we just talked about. You go through that iteration on the app, and we send it to one of our factory partners, whatever is closest to you in the world, like India, Turkey, and Hong Kong. The apparel factories are evolving along with us and our technology, sort of retooling the entire factory to think about orders of one instead of orders of one million.

We really believe that the future of apparel will be on demand—there won’t be inventory until someone needs it, and then it’ll be made for them.

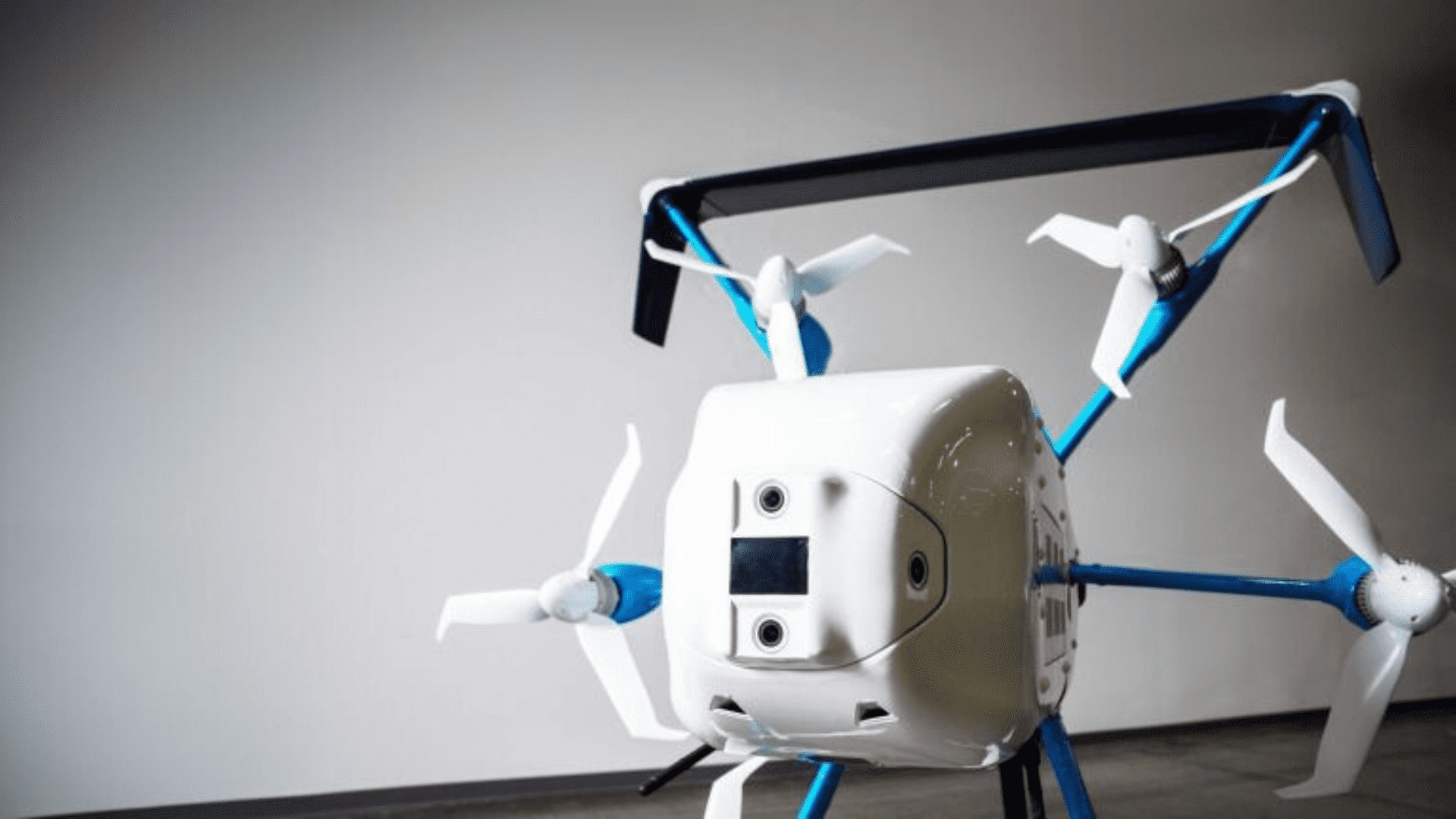

Phase Two is something that we just announced last fall in Time Magazine called 3D Weaving. Our Machine named Vega is a completely new manufacturing process where we have all these yarns coming in and seamless clothes that come out. The release of the very first product of this will likely be in the early part of 2023, and we’ll continue to slowly introduce it. It’s not only an incredible new fit technology for conventional denim but also a completely new category of clothing that can be faster, more efficient, and very local to completely minimize the carbon footprint of moving things around. So beyond just great fitting jeans, we have an exciting manufacturing and technology future as well.

TWT: What is your biggest challenge now?

KM: Measuring things is still hard, and it takes time—three to four weeks right now is kind of where we trend. Ultimately, we want to get that faster as we can keep thinking of more things you can automate and make more efficient. But so many of our customers tell us that they’ve been forced to wait for years to find a jean that fits, so they’re willing to wait those three extra weeks for unspun.

TWT: What do you think the biggest problem of the fashion industry is?

KM: I genuinely believe that climate is the biggest problem our generation will be forced to face whether we want to or not…Apparel is one of the top three dirtiest industries in the world. It’s massive—a lot of it is the core ingredients, a lot of it is overproduction, and a lot of it is transportation. I don’t think people understand the amount of energy that goes into making a T-shirt. I totally agree with things like taking shorter showers to conserve water, but if you skip buying one T-shirt, that’s the same as not showering for months at a time.

I think the apparel and fashion industry as a whole is incentivized to hide it…To me, the most fascinating part of this is how easy of a problem this is to fix: what’s better for the climate and what’s better for business is the same. If they’re making a hundred billion dollars worth of product this year as an industry that they’re going to invest in making and ping-ponging it across the Pacific a few times back to the US…it’s going to sit there, it’s not going get sold, and then they’re going to burn it.

There’s an opportunity for the industry to realize that they’re going to lose the hundred billion dollars they just spent and that they can instead make clothes that are better for the earth and better for their profits. That’s really where unspun exists and what we’re motivated by—this big climate goal and what it will take to get that snowball turning.

There’s already a lot of consumer sentiment. Gen Z will eat you alive if you claim to be sustainable and can’t back it up, which is awesome. The tide is starting to come in here, but I think it’s still going to take some of the things that a brand can’t say no to, like being better for the environment and being more profitable, to slowly start getting the ball rolling. Add in those ferocious Gen Zers that will eat you for faking it, and I think we’re headed in the right direction.

TWT: Your brand is bringing innovative AI technology to the fashion industry. What else do you see for the future of the fashion industry?

TWT: What makes you excited about the future of sustainable fashion?

KM: The bar for what consumers demand in terms of sustainability is ever-increasing, and consumers want you to put your money where your mouth is and prove that your brand is truly sustainable.

If you search “South America, mountains of clothes,” you’ll see what actually happens when people try to get rid of clothing. Even stuff that gets donated doesn’t always stay in the local community. Oftentimes clothes get piled up in bulk and shipped over to wherever will take them. It results in these massive dumping grounds of containers of clothes that no one wants…there’s piles and piles of it.

I think that the more this linear process becomes visible and the more we let ourselves think about what happens at the end of clothes, consumer demand for sustainability will grow and there will be more motivation around changing it.

Europe is already really leading the charge on legislation around sustainable fashion, making sure that there is enough proof that companies aren’t claiming things unless there’s documentation around it. This will be a hard phase for the apparel industry to adjust to, but it will be net better for the industry and environment. It will also benefit startups like unspun who are building core tech for brands to be more sustainable in a proven way. I’m excited about where the industry is headed.

We tried out unspun’s innovative and sustainable jeans for ourselves. See how it went HERE.