Scientists and researchers in Australia are working to build different types of smart robotic technology in order to save their dying coral reefs.

One group of researchers has created an underwater drone designed to help safeguard the Great Barrier Reef by neutralizing a coral-eating species of starfish that threatens the reef’s health. The robot, otherwise known as Rangerbot, is approximately the size of a briefcase and is equipped with a vision system that allows it to navigate and avoid obstacles underwater.

The vision system also allows the robot to identify crown-of-thorns starfish, creatures which are covered in venomous spines and “devastate large tracts of reef,” said Matthew Dunbabin, an engineering and robotics professor at Queensland University of Technology in Brisbane, Australia, and one of the researchers who built the bot.

Moving around using thrusters, Dunbabin states that the robot is able to identify its quarry with 99.4 percent accuracy. “Once the identification is confirmed, RangerBot can instigate an injection which is fatal for the crown-of-thorns starfish but doesn’t affect anything else on the reef,” he said in a statement.

In addition to killing the starfish, RangerBot is designed to monitor the reef’s health by creating 3D maps which track changes in the ecosystem. The drone is also capable of remaining underwater much longer than divers and venturing into areas too dangerous for humans.

“Having people in the field is always a liability,” said John Bruno, a University of North Carolina marine biologist who isn’t involved with the project. “This could really simplify things — there’s less training, you can take a smaller ship to get out to the sites, you don’t have to feed it. I can see a lot of benefits.”

The team is working with the Great Barrier Reef Marine Park Authority and the Australian Institute of Marine Science to obtain the necessary approvals for RangerBot. The ultimate goal is for RangerBot or similar robots to be used to monitor and protect reefs worldwide

Another type of robot is also being used to rescue Australia’s dying coral reefs. For years, scientists have worked through various methods to attempt to save the coral reefs including transplanting thousands of healthy and upgraded corals onto damaged reefs, but even this has not been enough to save whole ecosystems. The process is labor intensive, expensive, and slow because corals take approximately 3 to 10 years to grow an adult-sized skeleton depending on the species. Australian coral biologist Dr. Taryn Foster’s company, Coral Maker, is attempting to expedite this process.

Prior to working with coral reefs, Foster worked in her family’s masonry business. This is where she got the idea to use dry-casting machines to produce limestone shapes that resemble the natural skeletons of corals, thus providing young corals with the foundation they need to grow faster.

The first prototype of the Coral Maker skeleton is dome-shaped with six plugs where live coral fragments can be placed. The skeleton design takes inspiration from nature as many species (such as brain corals) grow in a dome shape. Dome-shaped skeletons, however, come with their own set of challenges.

“They’re not as easy to manufacture as something with a flat surface, they’re not as easy to pack on a pallet, they’re not as easy to glue stuff on.” Foster stated.

Foster continues to perfect the design with the goal of producing up to 10,000 pieces a day for only a few dollars, so that the process could be replicated in other factories. Once coral fragments are planted out of reefs using the premade skeletons, they could reach their full size in approximately 12 to 18 months.

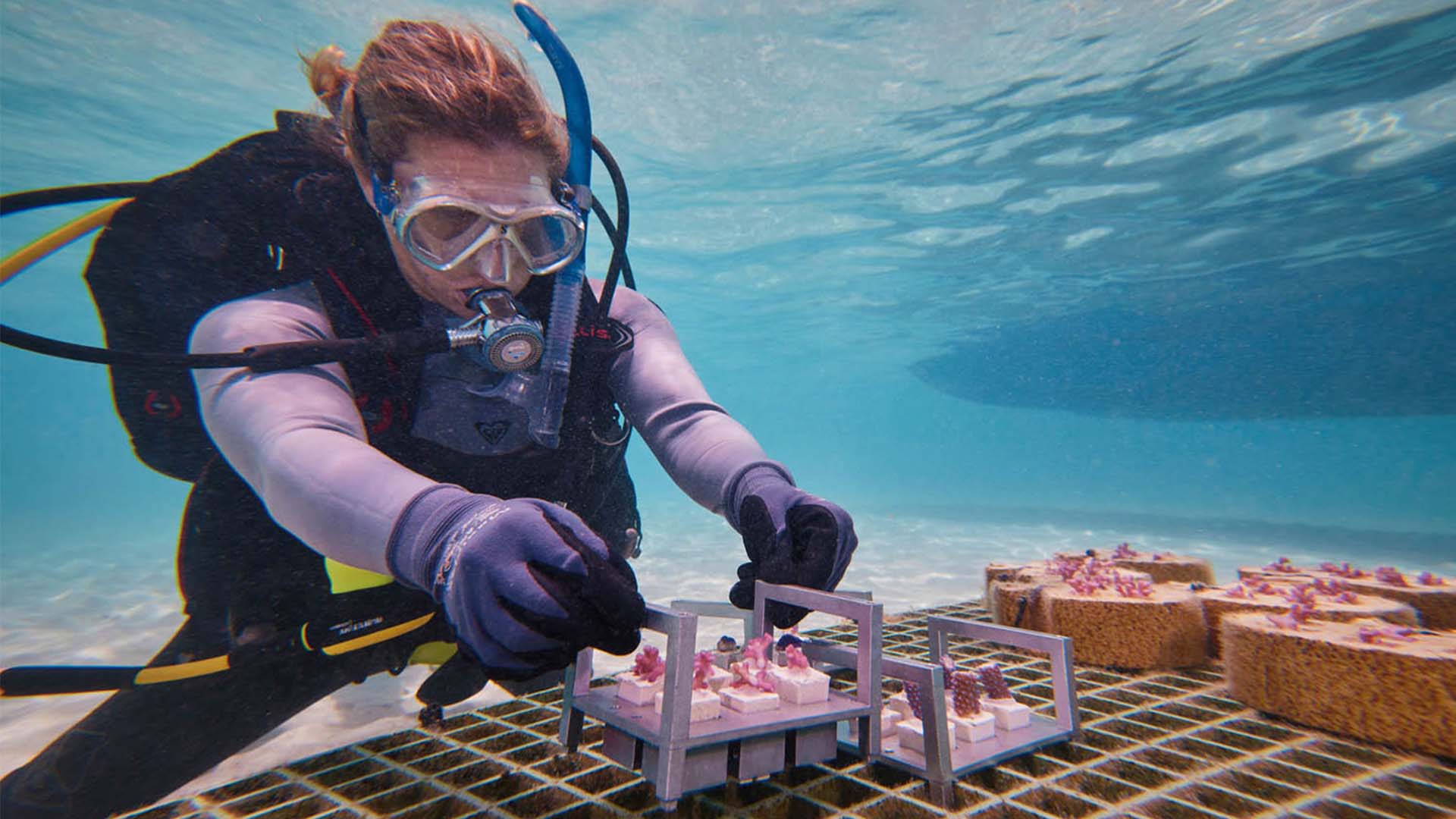

She has conducted a trial first batch of corals in premade skeletons for over a year on a coral farm near Abrolhos Island in Western Australia. On December 22, 2022, Foster and her colleagues also deployed a second batch of corals on a sandy patch on the underwater farm. In this trial, the premade skeletons were in the shape of a disc.

In order to produce approximately 1.7 million corals on 280,000 skeletons per year, Foster stated that the manual tasks on land will need to be automated. She’s currently working with researchers at the Autodesk AI lab in San Francisco to develop and train two types of robotic arms and image sensors. One is capable of cutting coral fragments into smaller pieces and gluing them into plugs while the other can implant the plugs into the limestone skeletons.

According to Foster, the ultimate goal is to have multiple projects on reefs and coastlines around the world. “I think of this as a delivery or scaling mechanism for these other technologies that people are developing, like coral propagation,” says Foster. “Just at a much faster rate and on a bigger scale.”