Researchers at the National Institute of Materials Science in Japan have developed a highly flexible alloy that could be used to make shape-shifting aircraft or superstrong artificial muscles.

The alloy, comprised of titanium and nickel metals, has the strength of steel but the stretchiness of rubber under certain environmental conditions.

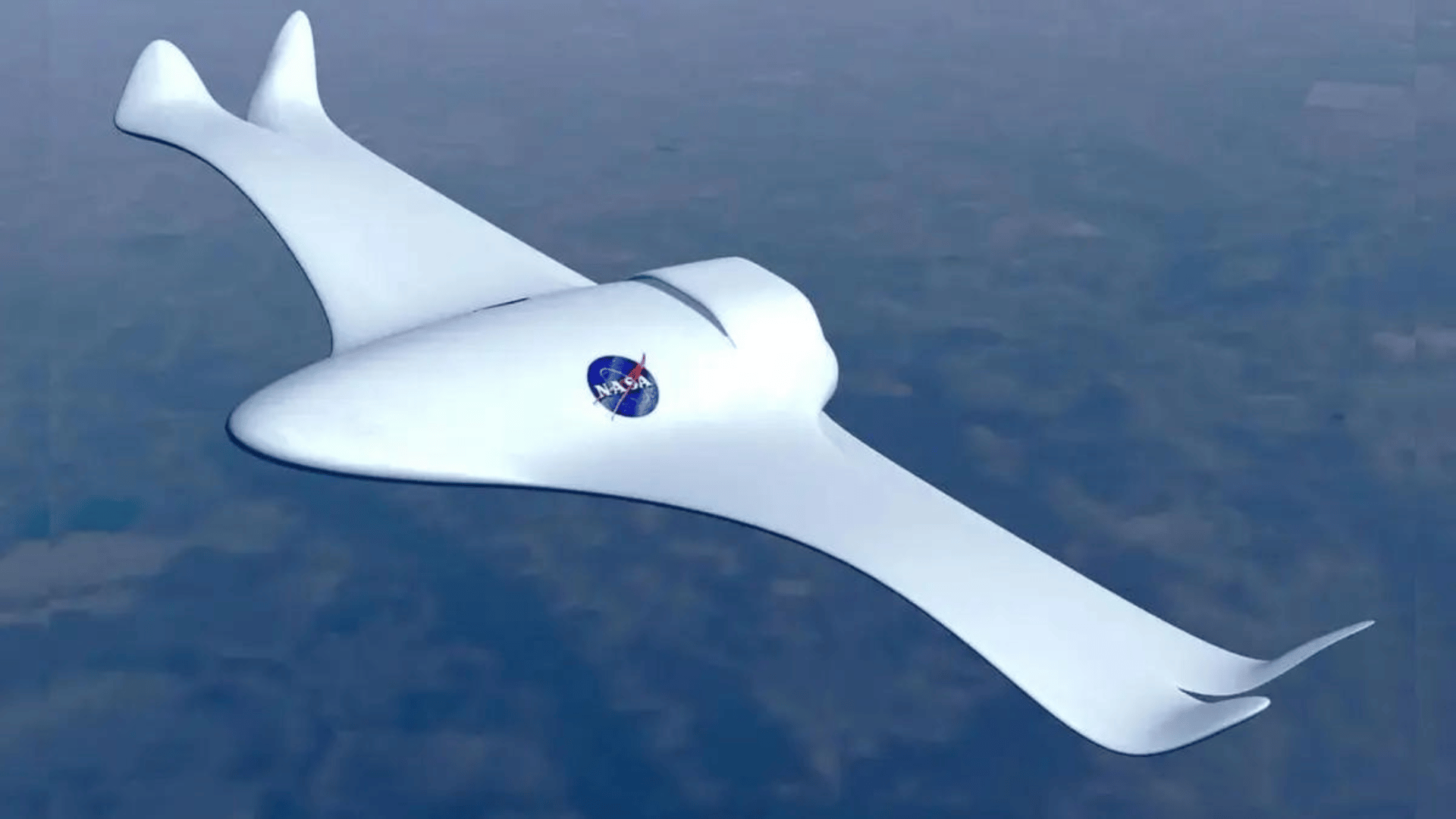

The challenge when creating this type of alloy is that strength and flexibility need to balance each other. Making an alloy more flexible would diminish its strength and vice versa. Therefore, while a flexible aircraft could deliver benefits for higher energy efficiency and faster transportation, that can’t come at the expense of passenger safety.

Previous research has shown that this type of alloy could stretch far higher than other metallic alloys and, when subjected to increased temperatures, return to its original form. The fact that this alloy could only remain flexible under specific temperatures, however, has presented a challenge to previous researchers.

A research team led by Xiaobing Ren, a professor at NIMS, devised a three-step procedure to make the alloy display these characteristics across a wide range of temperatures. The researchers began by deforming the alloy and elongating it by over 50 percent.

Next, they heated it to 572 Fahrenheit (300 degrees Centigrade) before elongating it again. Finally, the researchers elongated the alloy by only 12 percent.

By the end of the process, the material could withstand pressure about 18,000 times greater than normal atmospheric pressure. The strength performance of the material is comparable to steel but with 20 times more flexibility, and it can achieve this flexibility under temperatures ranging from minus 112 degrees Fahrenheit to 176 degrees Fahrenheit.

Ren explained to New Scientist that the alloy displayed these abilities because it behaved more like glass than metal. Unlike conventional glass, however, this alloy has areas where molecules are arranged in a manner that results in the material’s deformation rather than breaking.

The method of creating this material is straightforward, meaning it could be easily produced by other labs or on a large-scale industrial level.