Since the first hydrocarbon well was drilled in 1859, the drilling industry has continued to make improvements in safety, performance, and environmental protection. There’s no doubt that the original drillers from 100 years ago, in the world of boomtowns and gushers, would not recognize today’s modern high-technology drilling rig fleet when compared to the wooden derricks they built.

As time has passed, the principles of safety and responsible stewardship of the environment remain core values of the energy industry. Especially in today’s world, the prevention of injuries and reduction of environmental impact is a critical need universally, whether in oil, geothermal, or other forms of energy production/development.

The drilling industry’s advancements in technology harmonize with the significant improvements in safety protocols, training, and overall safety culture. By integrating new technologies into its operations, the energy industry has significantly reduced the risk of injuries to its workforce and minimized the environmental impact of operations.

Safety by design

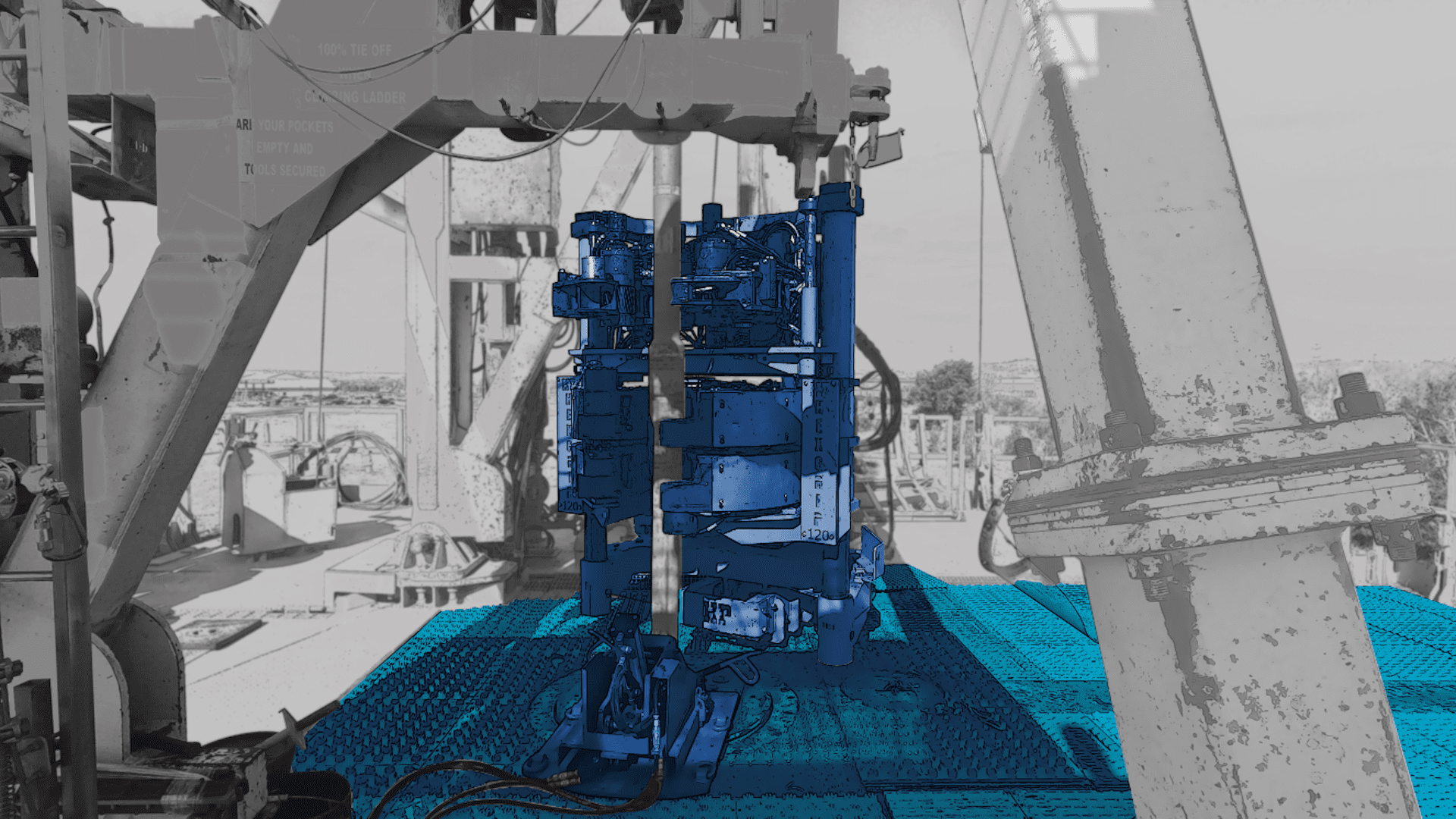

One of the most obvious benefits of new technologies comes in the form of improved safety for the individuals who perform work on the rigs. The technologies include mechanization and automation of historically manual tasks. By integrating machines and automated processes into the physically demanding portions of the work, rig workers are protected from many acute exposures, ultimately reducing the likelihood of chronic injuries.

Efficient rig moves

The ability to drill more wells without moving the drilling rig from one location to the next, using trucks

and cranes, has had a tremendous influence on personnel safety and environmental impact. This is accomplished by skidding the rig (sliding it from one well to the other), or walking the rig (using a hydraulics system at the base to transport over a short distance), instead of moving the entire drilling rig from well to well.

This has improved safety in two specific ways. First of all, by reducing the number of rig moves, and ultimately eliminating some, we have reduced one of the higher-risk activities of drilling a well. Additionally, reducing the frequency of rig moves reduces the impact on the environment and the community in which drilling activities are performed. Reducing heavy equipment used to move rigs also eliminates emissions and alleviates strain on the infrastructure required to move equipment.

The transition to long laterals

Over the past 50 years, the industry has transitioned from vertical wellbores, which have minimal exposure to the formations that contain energy, to horizontal wellbores, which allow the greatest exposure to the energy-containing formations. Drilling these wells using the lateral method has reduced the number of wells needed to produce a comparable amount of energy versus conventional vertical wells.

Horizontal drilling has also allowed energy producers to drill multiple wells from a central location, thereby reducing the overall footprint and amount of well sites constructed. This also reduces the impact on the environment. These improvements could never have been achieved without advancements in technology and the techniques used to target these critical sources of energy.

Reducing risk by reducing trips

Many tool and equipment improvements occur “downhole” – below the earth’s surface. As the length and depth of wells have increased significantly, so has the reliability of the equipment used in the wellbore to drill the well. Improving the reliability of downhole motor, bits, and drill string designs significantly reduces the number of “trips” needed to drill a well.

A “trip” is the process of pulling drillpipe from the wellbore or running the pipe back to the bottom of the wellbore. The manual work performed during a trip inherently increases the risk of an injury, and any time the drillpipe is removed from the wellbore, there is an increased risk of a well control event.

Imagine you are a fisherman and you drop your lure to the bottom of the ocean at 200 feet. How much work would it be to reel even a moderately sized fish into the boat? Now imagine that you are on a drilling rig and instead of hundreds of feet, the depth of the hole is over 20,000 feet. And, at approximately every 90 feet of pipe you pulled, you had to disconnect the pipe, move it out of the way, and then pull another 90 feet. As you can imagine, this work can be physically demanding. Fortunately, by using advanced tools and bits in the wellbore, we can reduce the number of trips by 50 percent, reducing the risk of personal safety, oil spills, and emissions.

A culture of safety

The safety of people and the protection of the environment are fundamental values of those who work in the energy industry. Although significant improvements have been made in how the industry provides access to geological energy sources, there is still work to do as the industry remains committed to providing the world with affordable and safe energy through the use of technology.

For more information on the innovations in the drilling industry, check out our full episode below.