3D Printing, or additive manufacturing, has made its way into the nuclear sector only within the past few years. Because of the incredibly strict safety requirements within the nuclear industry, any parts used in the nuclear industry must be reliable, durable, resistant to high temperatures, and must pass more rigorous QA and regulatory inspections than in any other industry. The first commercial installation and continuing safe operation from a 3D printed part in a nuclear power plant occurred in 2017.

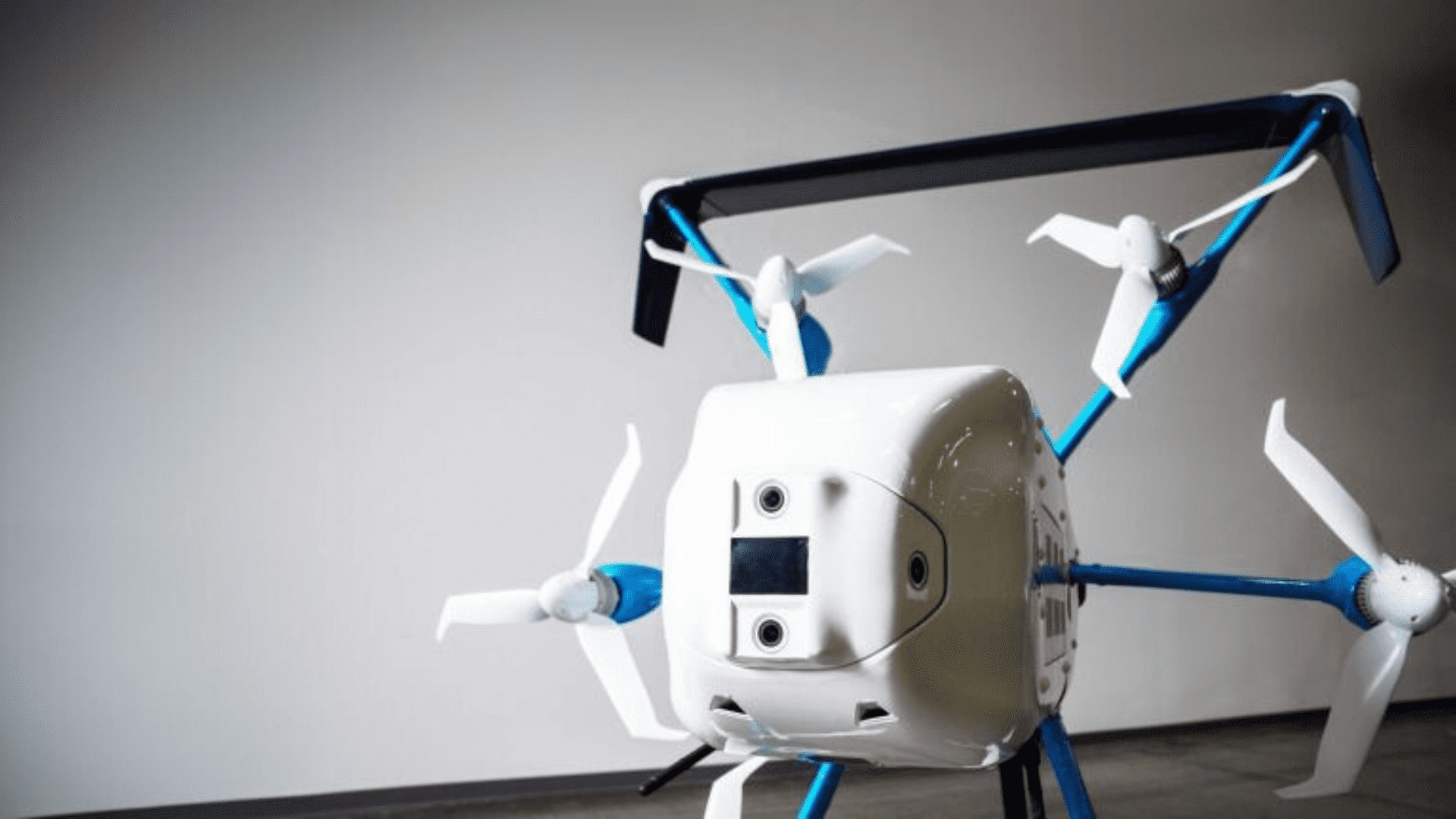

There are many obvious benefits to switching over to 3D printing parts, including cost-effectiveness and reducing a carbon footprint. Because of the benefits, the nuclear industry has begun to switch to 3D printing in various areas over the past few years. One of the most promising innovations taking place is that of developing micro-reactors. According to Forbes, these are small nuclear reactors (less than 10 megawatts) and capable of fitting on the back of a tractor-trailer. Oak Ridge National Laboratory, in partnership with U.S. Navy’s Disruptive Technology Lab, created the first 3D printed submissive hull for the Navy and this is roughly the size of a micro-reactor.

Westinghouse Electric Company has successfully integrated 3D printed thimble plugging devices. This is used in nuclear reactors to lower fuel assemblies into nuclear reactor cores. This part was integrated into Exelon’s Byron Nuclear Generating Station this Spring. Westinghouse also plans to become the first company to 3D printed component for nuclear fuel element into a commercial nuclear reactor. In addition, the Department of Energy’s Argonne National Laboratory in Illinois have begun using 3D printing for nuclear waste separation, which immensely increased the amount of recyclable fuel waste.

Oak Ridge National Laboratory (ORNL) has even begun work on a potential 3D printed nuclear core. According to Kurt Terrani, Transformational Challenge Reactor’s technical director, “We have been aggressively developing the capability to make this program a reality over the last several months, and our effort has proven that this technology is ready to demonstrate a 3D-printed nuclear reactor core…The current situation for nuclear is dire. This is a foundational effort that can open the floodgates to rapid innovation for the nuclear community.”