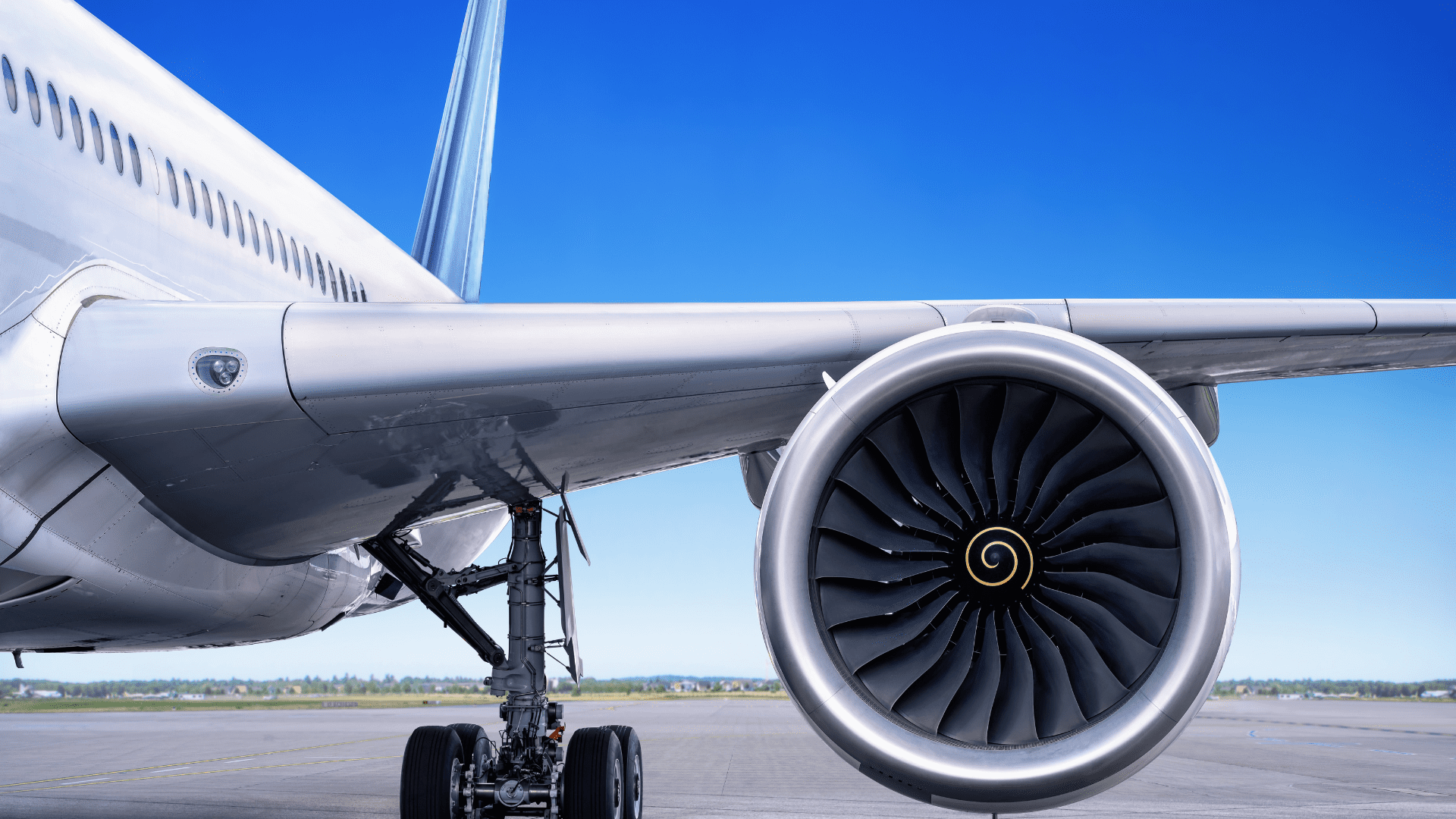

Hydrogen is a major part of a sustainable future, especially in the aviation industry. Many plans exist to make hydrogen-powered aircraft. However, that means building these vehicles from scratch that can be fueled by hydrogen. A team of researchers with ETH Zurich is developing jet engines that burn hydrogen rather than kerosene.

Jet engines must adapt to running on the new fuel. Before making the switch from kerosene to hydrogen, several factors need to be considered.

“Hydrogen burns much faster than kerosene, resulting in more compact flames,” explains Nicolas Noiray, Professor in the Department of Mechanical and Process Engineering at ETH Zurich.

Experiments by Noiray’s team provide an important foundation for this, which was published in a new study.

Vibrations are one problem that engineers want to minimize. About 20 fuel nozzles surround the engine’s combustion chamber in typical jet engines. The turbulent combustion creates sound waves that reflect off the chamber walls and have a “feedback reaction on the flames.” The sound waves and flames produce vibrations, inducing a heavy load on the engine combustion chamber.

“These vibrations can fatigue the material, which in the worst case could lead to cracks and damage,” said Abel Faure-Beaulieu, a former postdoctoral researcher in Noiray’s group. “This is why, when new engines are being developed, care is taken to ensure that these vibrations do not occur under operating conditions.”

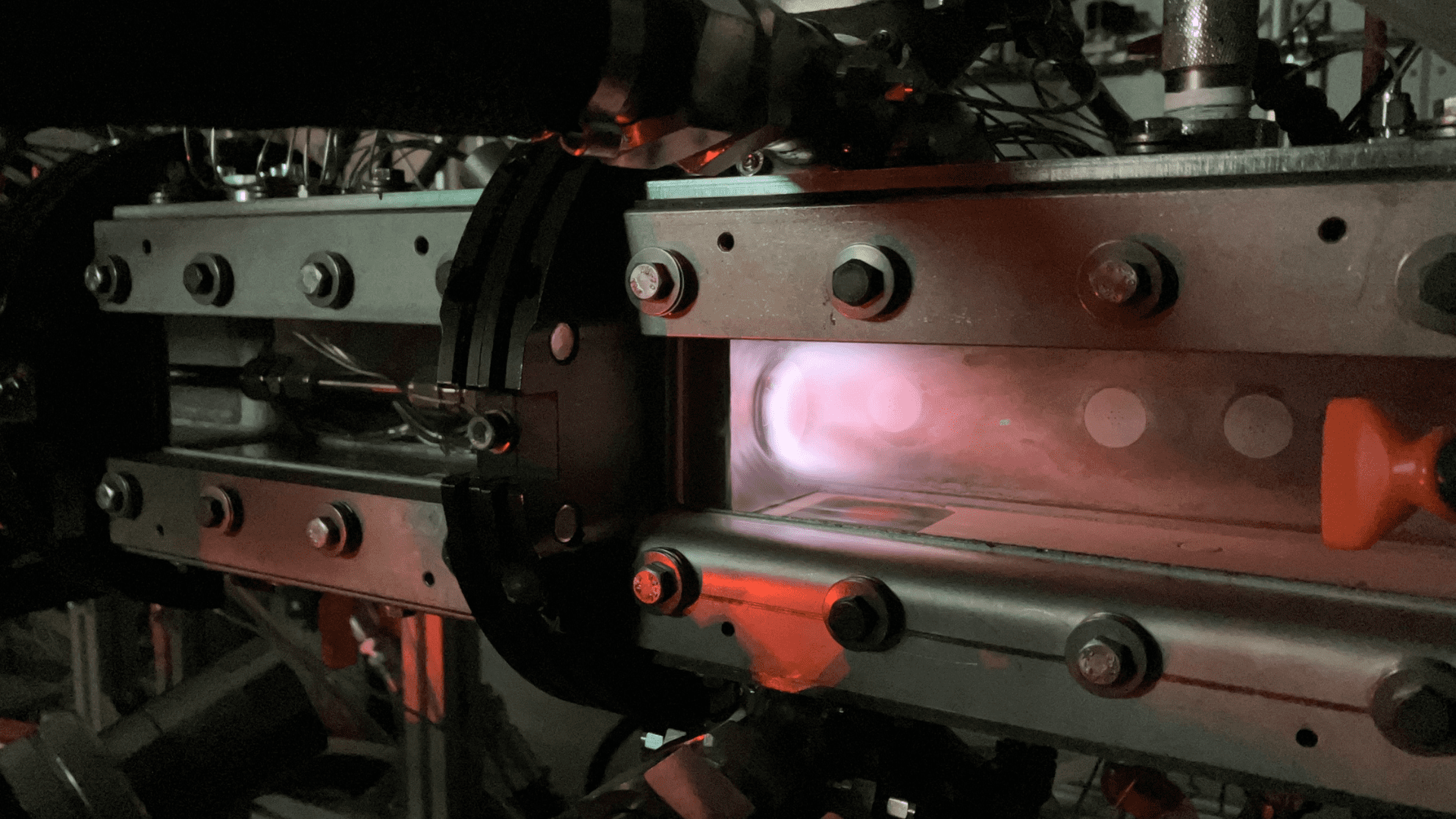

Testing Hydrogen Engines

When engineers developed the kerosene engine, they had to control those vibrations. They did this by “optimising the shape of the flames” along with the combustion chamber’s geometry and acoustics. However, the type of fuel impacts the interaction between sound and flame. This means engineers must find a way to control vibrations for a hydrogen engine.

Noiray measured the acoustics of hydrogen flames and predicted potential vibrations at an ETH Zurich facility.

“Our facility allows us to replicate the temperature and pressure conditions of an engine at cruising altitude,” Noiray said. The ETH researchers can also recreate the acoustics of various combustion chambers, enabling a wide range of measurements. “Our study is the first of its kind to measure the acoustic behavior of hydrogen flames under real flight conditions.”

In their experiment, the researchers used a single nozzle and then modeled the acoustic behaviors of the collection of nozzles as they would be configured in a future hydrogen engine. ETH Zurich said in a press release, “In a few years, the engine should be ready for initial tests on the ground, and in the future, it could propel the first hydrogen-fuelled aircraft.”

Noiray doesn’t think that the greatest challenge is developing the engine or hydrogen tanks for aircraft. “Humanity has flown to the moon; engineers will undoubtely be able to develop hydrogen planes,” he said. Planes aren’t enough in his opinion. Creating an entire infrastructure for hydrogen aviation is a major challenge.

According to researchers, “Achieving this within a reasonable timeframe requires a concerted effort now.”

But why hydrogen?

Professor Noiray said, “For passenger and cargo aircraft, synthetic fuels are the only alternative to today’s kerosene, and hydrogen is the most economical to produce sustainably.”