To keep up with the growing demand for copper, mining companies are searching for ways to leverage new technologies and innovations to increase their copper output and decrease the environmental impact of the mining process.

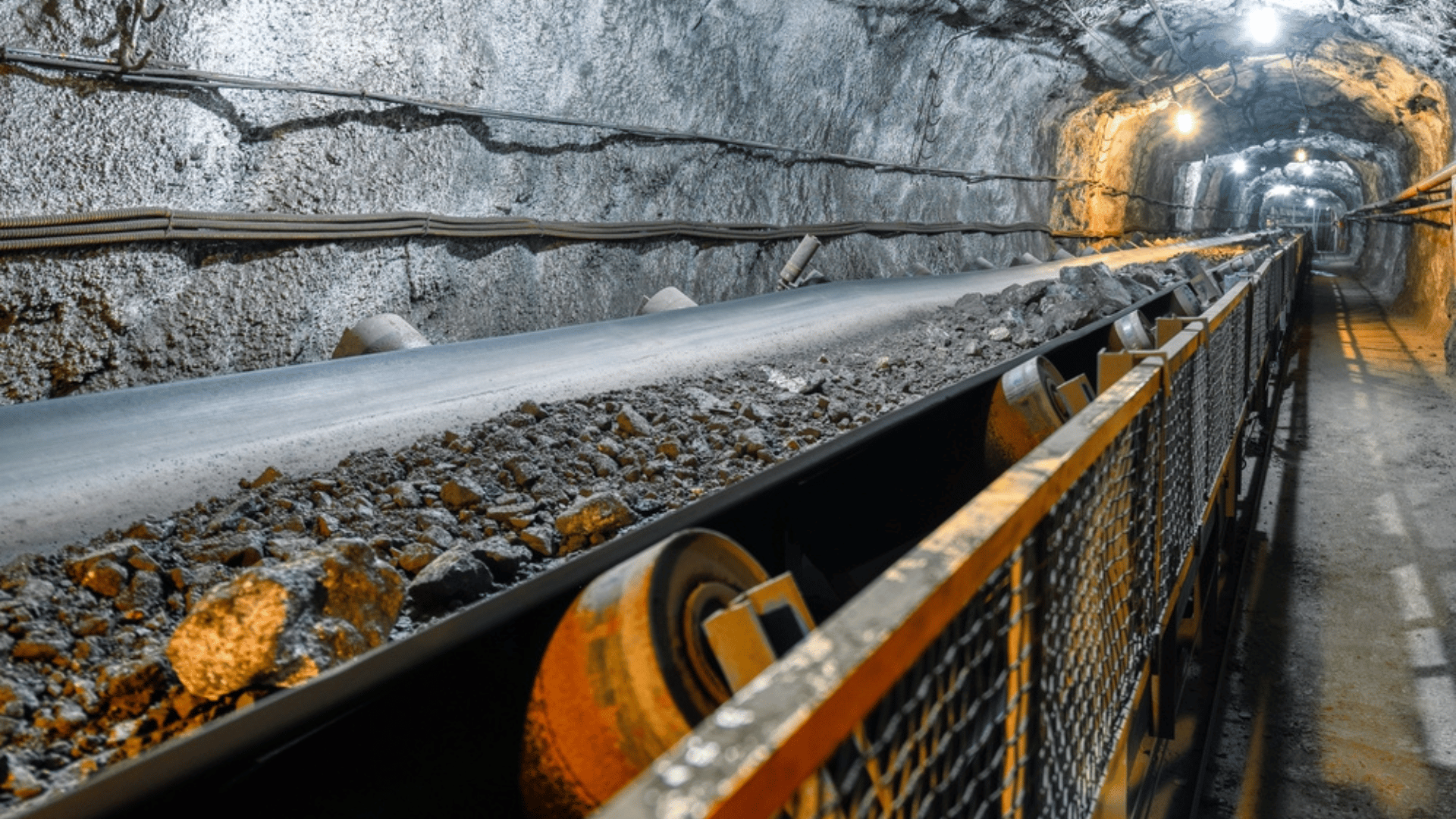

Leaching

Freeport-McMoRan and other mining companies are working on leaching, a technology that allows them to recover copper from low-grade sulfide deposits that may not have been commercially viable in the past. The process involves using percolating chemical solutions to leach out metals.

After mining, transporting, and crushing to a consistent gravel size, the crushed ore is piled into a heap on top of an impenetrable layer on a slope. The leaching reagent (dilute sulfuric acid) is sprayed through sprinklers to the top of the pile and moves down through the heap, dissolving the copper from the ore. The resulting leach solution of sulfuric acid and copper sulfate is then collected in a small pool.

“Leaching has very limited capital requirements, the operating costs are low, there are no carbon emissions and generally no permitting required, which are all big parts of traditional mining,” Richard Adkerson, CEO of Freeport-McMoRan, stated to CNBC.

Automation and Electrification

Increasing automation and electrification in the copper mining industry can increase safety, efficiency, and sustainability while helping miners achieve net-zero goals. For example, Freeport-McMoRan has introduced robotics at its Grasburg underground mine in Indonesia and is working with Caterpillar on large battery-electric haul trucks.

Haul trucks run all day and use a lot of diesel, which can negatively affect the environment. Freeport-McMoRan is also working with Bagdad Operations, an open pit mine in Arizona, to integrate autonomous technology into their haul trucks. This would allow the trucks to be driven remotely, rather than operated by a person. Instead of having a human inside of the haul trucks at all times, which can be dangerous, a human would instead be stationed inside an operating room to monitor the trucks and ensure that they’re operating at maximum efficiency.

Alternative Ores

The mining industry is also innovating by attempting to find new ways to work with different types of ores. Copper mining typically involves sulfide-bearing ores and their mining process involves mining, concentrating, smelting, and refinings. The steps of concentrating and smelting negatively impact the environment because they require a lot of energy.

Freeport-McMoRan is currently attempting to change the industry by working with different types of ores that are non-sulfide-bearing solvent extraction and electromining. This would allow them to eliminate the concentration and smelting steps of the process, lower their carbon footprint during the mining process, and achieve twice as much copper from the same area of land.

Explore Tomorrow's World from your inbox

Get the latest innovations shaping tomorrow’s world delivered to your inbox!

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

Bio-surfactants

Copper is typically mined in one of two ways: either by soaking crushed ore in a solution of water and chemicals that allow target minerals to float to the surface or by dissolving the rocks in acid (also known as leaching) allowing minerals to float to the top. By using bio-surfactants, or chemicals from microbes that break the surface tension of a given material, companies have the potential to increase yields because they’re potentially better than existing chemicals at breaking the surface tension of rocks and binding the copper.

Adding them to the soaking process allows more copper to float to the surface, ensuring that less goes to waste. According to Locus Fermentation Solutions, bio-surfactants increase copper yields by 7% and save energy because less rock needs to be crushed.

Tune in to the Science Channel to watch Beneath the Surface at 10 AM EST on Saturday, April 27!