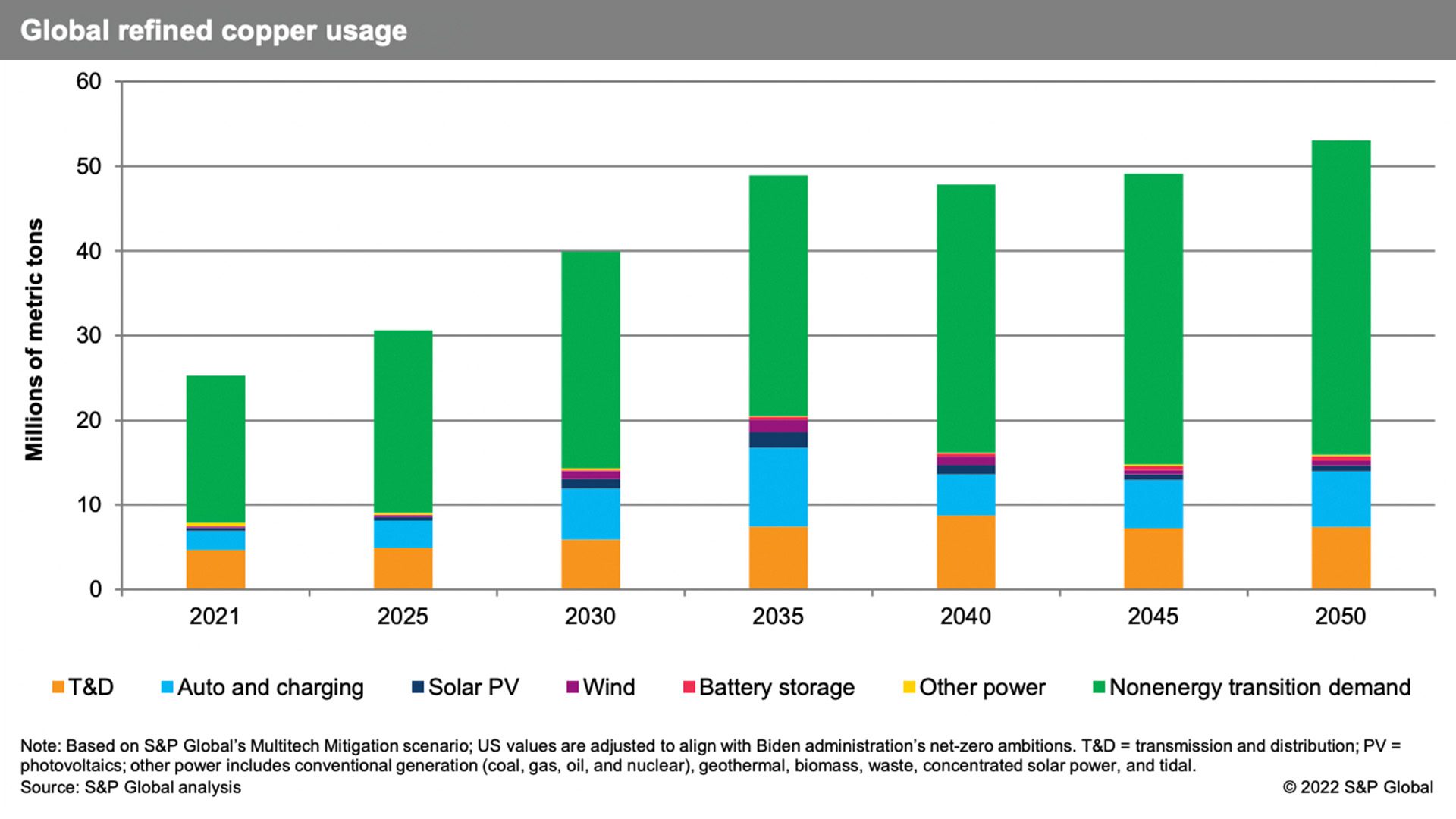

In a recent study, S&P Global describes copper as the metal of electrification and an essential part of reaching the global goal of net-zero emissions by 2050. As a result, copper demand is projected to double by 2035, from the current demand of 25 million metric tons (MMt) to about 50 MMt by 2035.

Why Copper?

Copper is the oldest known metal, dating back over 10,000 years ago. It has been a preferred metal in electricity applications since Nikola Tesla and Thomas Edison, and its projected demand shows that this will not change soon.

The metal has four key properties that make it ideal for a variety of applications: conductivity, ductility efficiency, and recyclability.

Copper has the highest electrical conductivity rating of all non-precious metals and can easily be shaped into pipes, wires, or sheets. Its thermal efficiency is about 60 percent greater than aluminum, meaning that it can remove heat rapidly. Copper is also 100 percent recyclable and remains fairly affordable, making it a key part of renewable energy transition plans.

How is Copper Used?

The projected increase in copper demand can be attributed to its vitality in many growing industries.

Renewable Energy

Renewable energy systems can require up to 12 times more copper compared to traditional energy systems. As the adoption of clean energy technologies like wind turbines, solar photovoltaics, and nuclear reactors grows, so will the need for copper.

For example, there are about 5.5 tons per megawatt of copper in solar power systems. Copper is used in its wires to conduct electricity, heat exchangers to transfer solar energy to heat water or air, and more. Because of the increase in solar power installations, copper demand for annual solar photovoltaic installations could more than double by 2030. In one projection from 2018 to 2027, 1.9 billion pounds of copper will be needed to power 262 GW of new solar installations.

Electric Vehicles

A great deal of copper is also needed for electric vehicles, from their batteries, windings, wiring, charging infrastructure, and more. For example, a BYD electric vehicle charging port running from 3.3kW to 200kW contains between two to 17 pounds of copper. As a result, electric vehicles can require up to four times as much copper as gasoline vehicles. With the projected increase in electric vehicles, copper will play a necessary role.

Copper Mining

As these industries continue to ramp up, so will the pressure for new copper projects. However, operating mines and proposed projects are currently not meeting copper’s projected demand. The report warns, “Unless the impending supply gap [of copper] is closed in a timely way, Net-Zero Emissions by 2050 will be short-circuited and remain out of reach.”

To optimize and improve the copper mining process, many companies have implemented plans. For example, mining company Teck uses a technology transformation program called RACE which stands for Renew, Automate, Connect, and Empower. As Don Lindsay, Teck’s President and CEO, explains, “As we look to the future, we will continue to leverage digital innovation to more efficiently and sustainably produce the metals and materials needed for a low-carbon world.”

Teck’s Highland Valley Copper Operations in Canada is successfully using RACE’s automation and machine learning models that use real-time information from flotation processes like chemical addition and equipment settings. As a result, there has been a three percent increase in copper recovery. In combination with other simulation models that track ore characteristics, data analytics that support more informed lasting decisions, and more, the site has realized a 15 percent increase in mill throughput capacity.

For more information on mining, check out sustainable mining around the world and how this flooded mine provides the perfect scuba diving experience.

For more information on Teck and its RACE program, we visited Highland Valley Copper Operations. Check it out below: